Our submersible pumps

Our portfolio includes both high-pressure submersible pumps for coolant supply and medium-pressure flushing pumps for machine tools / filter systems / and much more

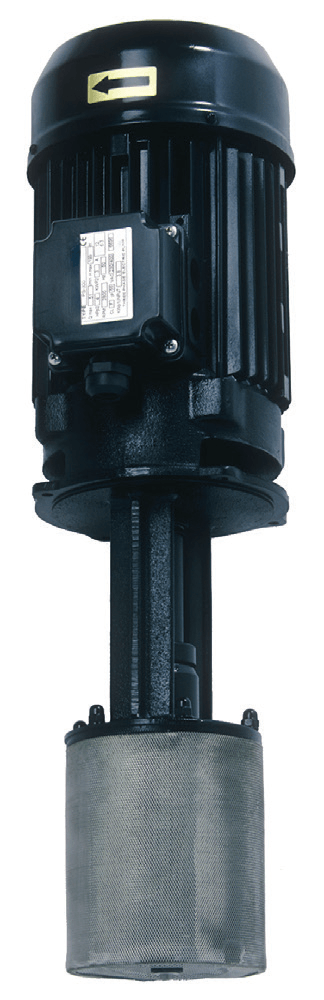

HTP high pressure submersible pumps

Our HTP pumps have been tried and tested thousands of times. The very compact design avoids installation problems in many cases, since the installation depth is considerably shorter than that of our competitors. This simplifies the installation effort enormously.

ETP medium pressure submersible pumps

The ETP series submersible pumps are designed to pump large volumes at low pressure. These pumps are often used especially as flushing pumps or as so-called cover-coolant pumps.

HTP series: high-pressure submersible pumps

HTP(M) 55 / HTP 170

- are mounted directly in the original tank of the machine instead of the original pump can be retrofitted to almost any machine tool offer higher pressure

Areas of application:

- Coolant supply in machine tools, rinsing of covers, apparatus and mechanical engineering, filter systems

conveying media

- Water coolant emulsion, low-viscosity cutting oils

To be observed when using in contaminated liquids

- Dirt content: max. 50 g/m³Grain size: max. 0.5 mmWithout abrasive components such as those found in grinding machines

Structural design:

- Pump housing: GG 20 Motor shaft: Stainless steel VA 1.4305 Impeller: Brass MS 58

diving depth:

- HTP55: 195 mmHTPM55: 250 mmHTP170: 300 mm

| Technical specifications | unit | HTP(M) 55 | HTP 170 |

|---|---|---|---|

| max pressure | bar | 7 | 20 |

| max flow rate | L / min | 57 | 51 |

| max. media temp. | °C | 50 | 20 |

| Weight | kg | 12 | 35 |

| voltage | V | 3-Phase 200/400V | 3-Phase 200/400V |

| frequency | Hz | 50 | 50 |

| performance | kW | 0,9 | 3 |

| rated current | A | 3,6 / 2,5 | 9,6 / 6,3 |

| number of revolutions | 1 / min | 2800 | 2800 |

ETP series: medium pressure submersible pumps

ETP 80 / ETP 125

Areas of application:

- Coolant supply, rinsing of the machine bed and covers on machine tools, pumping of coolant emulsion and low-viscosity oils into external filter systems and temperature control units

conveying media

- Water emulsions, low-viscosity cutting oils

To be observed when using in contaminated liquids

- Dirt content: max. 100 g/m³ Grain size: max. 1 mm

Constructive execution

- Pump housing: Aluminum Motor shaft: Stainless steel Impeller: ETP80: 1.4301 / ETP125: MS 58

diving depth:

- ETP80: 250mm or 330mmETP125: 250mm

| Technical specifications | unit | ETP 80 | ETP 125 |

|---|---|---|---|

| max pressure | bar | 0,8 | 1,5 |

| max flow rate | L / min | 230 | 310 |

| max. media temp. | °C | 50 | 50 |

| Weight | kg | 13 | 14 |

| voltage | V | 3-Phase 200/400V | 3-Phase 200/400V |

| frequency | Hz | 50 | 50 |

| performance | kW | 0,9 | 1,1 |

| rated current | A | 4,5 / 2,4 | 6,5 / 3,6 |

| number of revolutions | 1 / min | 2800 | 2800 |